The difference between industrial capacitive screen and resistance screen

With the development of The Times, the application range of industrial displays continues to expand, and its "figure" can be seen in various public scenes. In industrial production, leaving the mouse and keyboard, if equipped with a touchable display will make the operation more convenient, improve production efficiency, and better complete the work. So in industrial production, in addition to improving work efficiency, we also need to consider the touch stability of industrial displays, so today Suzhou Haite introduced is the difference between industrial display capacitive screen and resistance screen, which is more suitable for application in industrial production?

First、The properties and working principle of the resistance screen are introduced

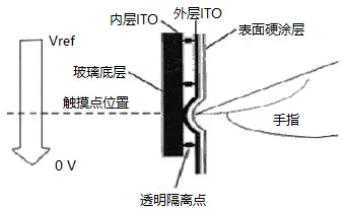

1) Properties: The resistive screen, known as the resistive touch screen, commonly known as the "soft screen", is different from the capacitor screen structure, only three layers, the inner layer is glass, the outer layer is a film, and the adjacent side of the film and glass are coated with ITO.

2) Resistance screen working principle:

The structure is composed of a lower line (glass or film material) conductive ITO layer and an upper line (film material) conductive ITO layer. The middle is separated by a small insulation point, when the touch screen surface is not under pressure, the upper and lower lines are open. Once the pressure is applied to the touch screen, the upper and lower lines are switched on, the controller applies the drive voltage in the X coordinate direction through the conductive ITO layer of the lower line, and detects the voltage in the X direction through the probe on the conductive ITO layer of the upper line, thus calculating the X coordinate of the contact. By changing the direction of the applied voltage through the controller, the Y-coordinate of the electric shock can be measured to determine the location of the electric shock. The capacitive screen supports only a single touch.

Second、 capacitor screen properties and working principle

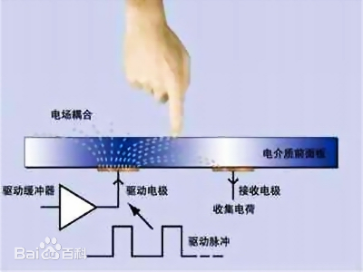

1) Properties: Capacitive screen, all known as capacitive touch screen, commonly known as "hard screen", is a four-layer composite glass screen, from the inside out, the beginning is ITO, to ensure the working environment; Then there's glass; The back is also ITO coating, used as a working surface; The fourth layer is the silica glass protective layer. The capacitive screen uses the current induction of the human body, which can be understood as the need to touch the medium with bioelectricity to touch.

2) Capacitive touch screen working principle:

Capacitive touch screen technology uses the human body's current induction to work. The capacitive touch screen is a four-layer composite glass screen, the inner surface of the glass screen and the interlayer are coated with a layer of ITO, the outermost layer is a thin layer of silica glass protective layer, the interlayer ITO coating as the working surface, four electrodes are drawn from the four corners, and the inner ITO layer is the shielding layer to ensure a good working environment. When the finger touches the metal layer, due to the human electric field, the user and the touch screen surface form a coupling capacitor, for high frequency current, the capacitor is a direct conductor, so the finger draws a small current from the contact point. The current flows from the electrodes on the four corners of the touch screen, and the current flowing through the four electrodes is proportional to the distance between the finger and the four corners, and the controller obtains the position of the touch point through the accurate calculation of the ratio of the four currents. The capacitive screen supports multi-touch.

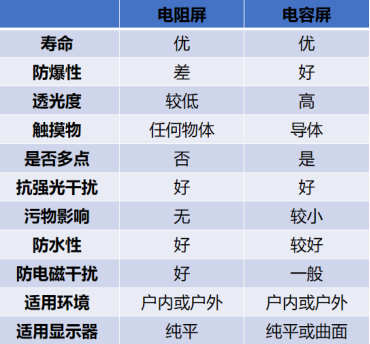

Third、the advantages and disadvantages of capacitance screen and resistance screen:

Fourth、 so what is the choice of capacitance screen or resistance screen?

When choosing the right industrial LCD screen and industrial touch screen, it is necessary to decide according to the application environment of the product, the application population and the product market. The capacitive touch screen and the resistive touch screen are usually selected through cost, accuracy, damage resistance, environmental adaptability and other aspects. Users still need to choose the most cost-effective products according to the specific use needs. For more details, please consult Suzhou Haite.